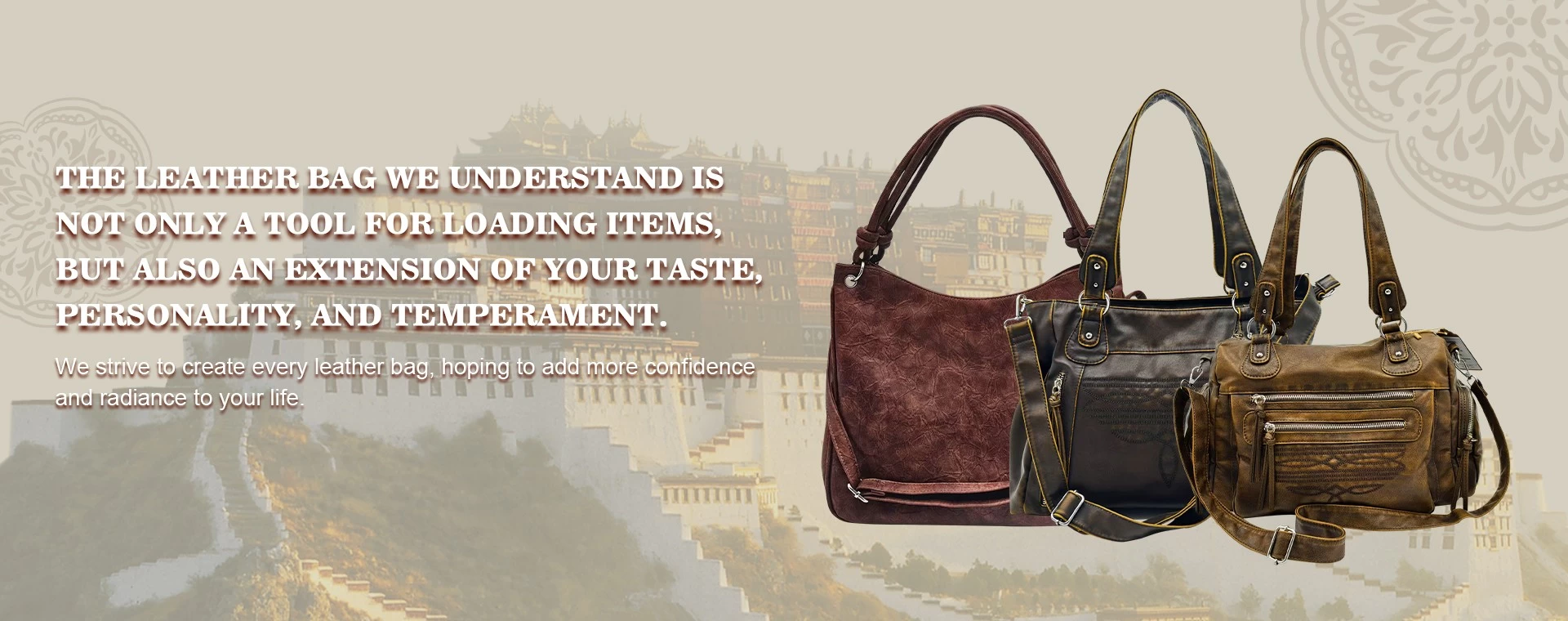

Guangzhou Artisan Workshop Blends Tradition with Tech in Vegan Leather Revolution

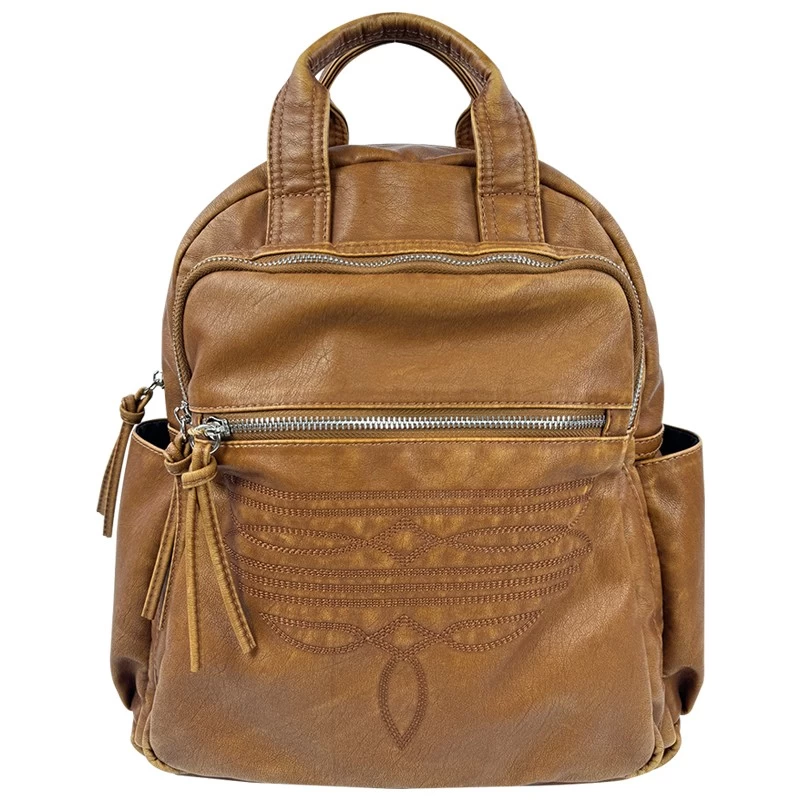

In Guangzhou’s bustling handbag manufacturing district, one factory is rewriting the rules of ethical fashion. The workshop behind the Ethnic Style Crossbody Bag GW9169—a vegan leather piece featuring tribal motifs and hand-burnished edges—has become an unlikely case study in harmonizing ancient craftsmanship with 21st-century efficiency.

The Algorithmic Artisan

While most heritage brands resist automation, this factory has developed a hybrid model:

AI-Assisted Pattern Cutting: Laser-guided tools optimize vegan leather usage, reducing waste by 22% while preserving hand-cut detailing.

Blockchain Craftsmanship Certificates: Each bag’s QR code reveals its artisan’s profile,stitching time (averaging 3.2 hours per unit), and even the solar energy consumed during production.

Robotic Quality Assistants: Though every stitch is human-made, (Low MOQ Crossbody Bags china) AI cameras now augment the "look, touch, pull, test" inspection, flagging micron-level stitching deviations invisible to the naked eye.

"We’re not replacing hands with machines—we’re giving masters superpowers," explains production lead Wang li, showing how AR glasses help artisans visualize pattern alignments in real time.

The Slow Fashion Accelerator

Despite its meticulous 28-step process, the factory achieves surprising agility:

Dynamic Sampling: New shape prototypes are 3D-printed overnight, slashing development time from 12 days to 72 hours for urgent buyer requests.

On-Demand Dyeing: A proprietary water-based coloring system lets clients like Anthropologie and &Other Stories customize the Cognac and Green hues within 5 days, eliminating overproduction.

Floating Factories: During peak seasons, modular workstations expand into nearby villages, training rural craftspeople in heritage techniques while doubling output capacity.

The Carbon-Neutral Couture

The GW9169’s vegan leather—developed from apple pulp and recycled cotton—has unexpected upsides:

Passed Luxury Tests: Rigorous 72-hour load tests proved its durability matches traditional leather, surprising even skeptical buyers from Italy.

Biodegradable Packaging: Filling paper is embedded with basil seeds; plant the wrapper to grow herbs—a viral TikTok trend (#BagThatGrows) driving B2C demand.

Energy Positive: Solar panels on the workshop’s Qing Dynasty-style roof generate 130% of operational needs, selling excess back to Guangzhou’s grid.

Global Artisan Economy 2.0

The factory’s tech-meets-tradition approach is reshaping export dynamics:

Micro-Batch Globalization: A recent 500-unit order for Parisian boutique Merci combined Ethiopian motifs with Breton stripes, delivered in 45 days via AI-optimized sea-air hybrid logistics.

Craftsmanship NFTs: Limited editions come with digital twins,(Affordable Bags Purses in china) allowing collectors to virtually "tour" the workshop where their bag was born.

RCEP Advantage: Tariff-free access to ASEAN markets has spurred collaborations with Indonesian batik artists, blending techniques into future collections.

"This proves craftsmanship isn’t retro—it’s the ultimate innovation," says Vogue International’s sustainability editor. As fast fashion giants scramble to emulate its model, this Guangzhou workshop quietly stitches its next revolution: a 2026 collection rumored to integrate self-healing vegan leather.

Order Spotlight:

MOQ 500+ with 30% deposit

Samples: 5-12 days (express shipping to EU/US in 48hrs)

Carbon-offset shipping options available

Contact: 435271631@qq.com/ +86-189 3883 2968