Guangzhou's luggage manufacturing industry embarks on a new chapter of intelligent transformation

As a key node in the global luggage supply chain, Guangzhou's luggage industry has recently embraced a wave of intelligent transformation. A leading wholesaler has pioneered the upgrade of its intelligent warehousing system, increasing its average daily order volume to 32,000 and shortening its response time to six hours. This marks a breakthrough in the transformation of the traditional wholesale model to a digital supply chain.

Building an Intelligent Manufacturing System

The company's intelligent production base consists of three core modules:

• AI Pattern Room System: Using 3D modeling technology,(OEM Custom Bags supplier) the pattern-making cycle is reduced from 7 days to 48 hours, allowing customers to modify designs online in real time.

• Flexible Production Line: 12 automated assembly lines can simultaneously process orders for different materials, such as PU leather, canvas, and nylon, with a switchover time of just 15 minutes.

• Intelligent Quality Inspection Center: Equipped with high-precision optical inspection equipment, the center achieves a 99.7% defect detection accuracy rate, an 8-fold improvement over manual inspection efficiency.

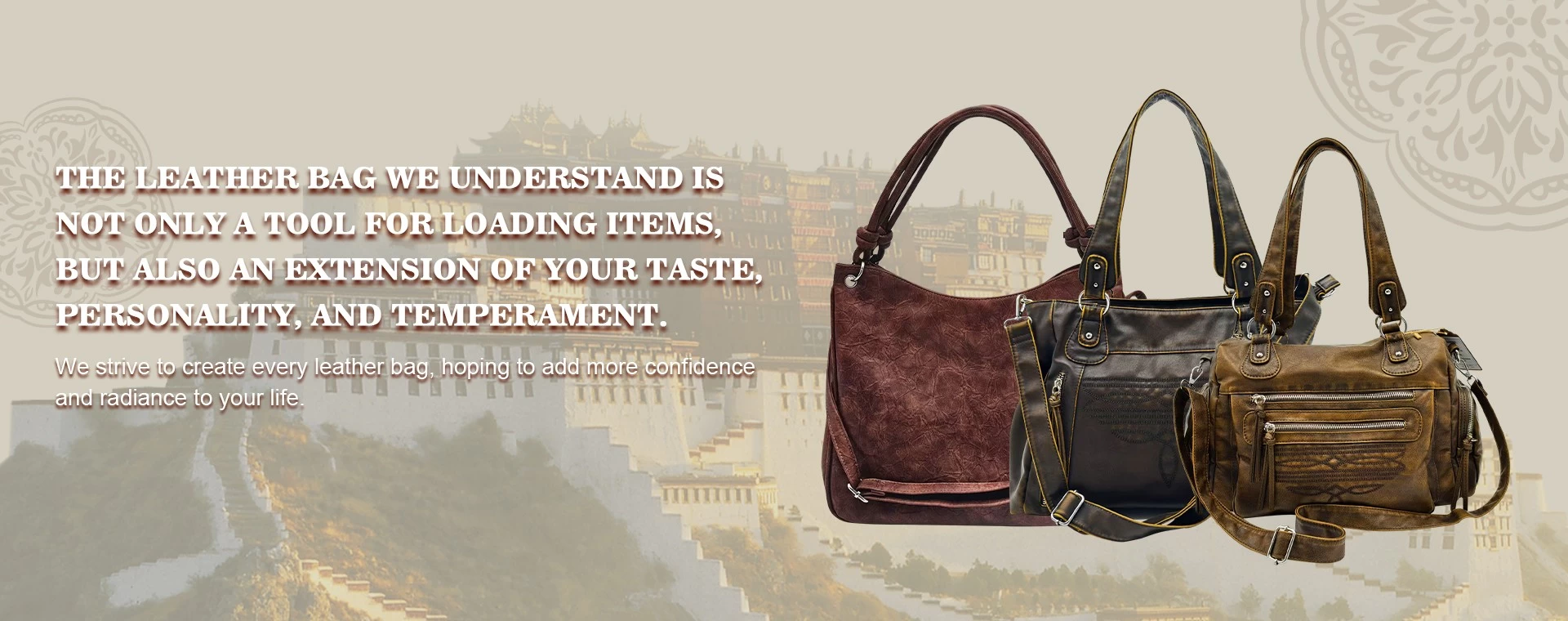

Wholesale Ladies Bags custom design

Sustainable Production Practices

In response to global environmental trends, the company has established a green supply chain management system:

✓ Recycled materials cover 75% of its product lines, reducing virgin plastic use by over 800 tons annually.

✓ GRS (Global Recycled Standard) certification makes it a designated supplier for fast fashion brands such as ZARA and H&M.

✓ The photovoltaic power generation system meets 30% of the park's electricity needs, reducing annual carbon emissions by the equivalent of planting 12,000 trees.

Upgrading Cross-Border Service Capabilities

To address shifts in global procurement demand, the company is building a digital trade infrastructure:

Developing a multilingual B2B procurement platform with support for VR virtual factory inspections

Overseas warehouses in Europe and the United States achieve rapid 48-hour replenishment, increasing inventory turnover by 40%

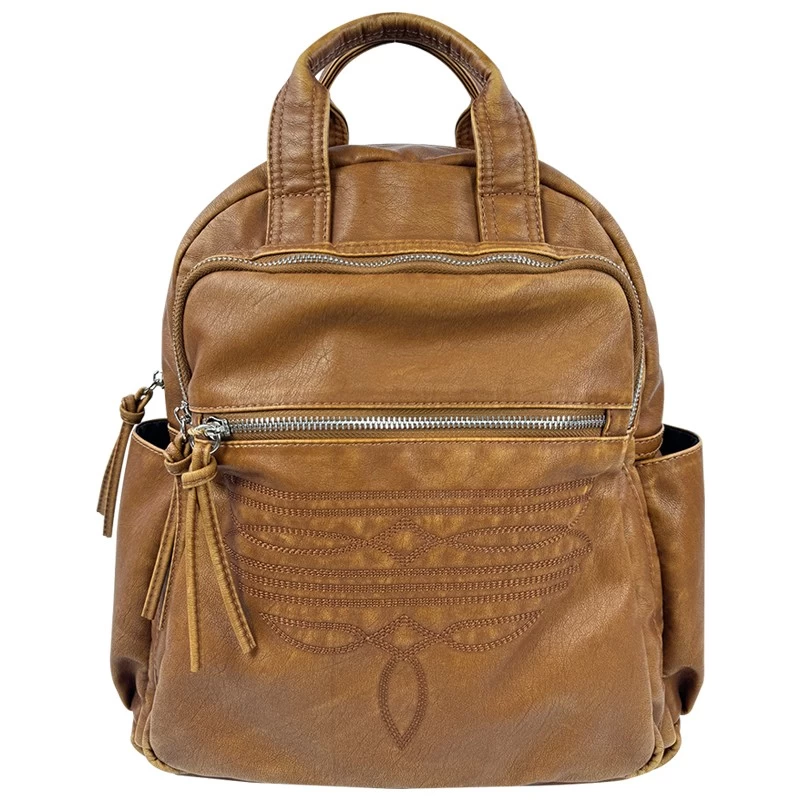

The TikTok livestreaming base, (Backpacks bulk order manufacturer china)staffed by a multilingual team of livestreamers, facilitates over $2 million in cross-border orders per month.

"Digitalization isn't optional, it's a must," said the company's head. "We are transforming 30 years of manufacturing experience into data assets to help global buyers reduce decision-making costs." The company's service network currently covers 83 countries, with cross-border e-commerce orders increasing by 217% year-on-year in the first half of 2025.

Industry Observation

Recent data from the China Baggage Association shows that the Guangzhou Industrial Belt contributes 38% of China's luggage exports, with the average order churn rate for companies undergoing smart transformation reduced by 26 percentage points. With the deepening implementation of the RCEP agreement, digital capabilities are becoming a core competitive advantage for exporting companies.